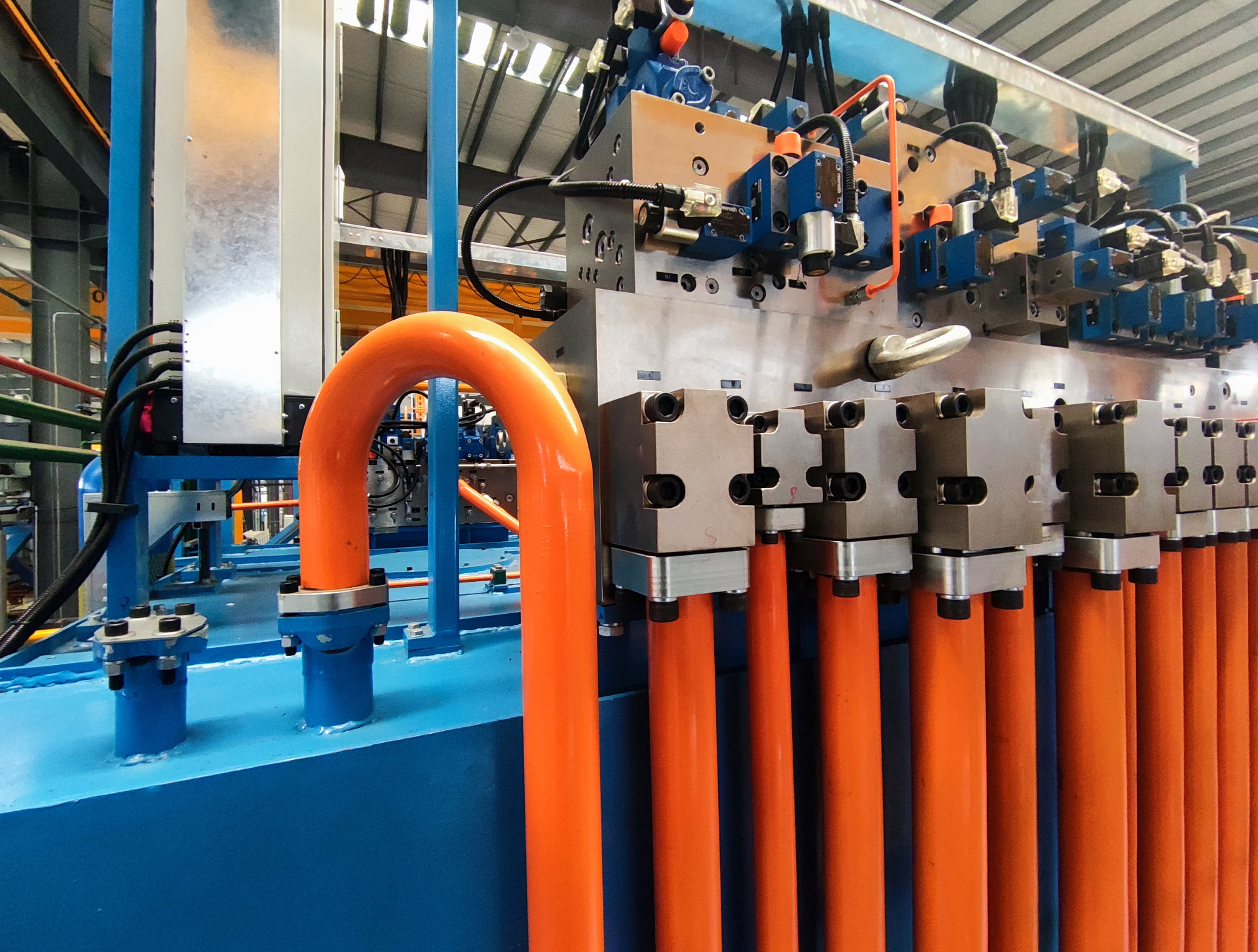

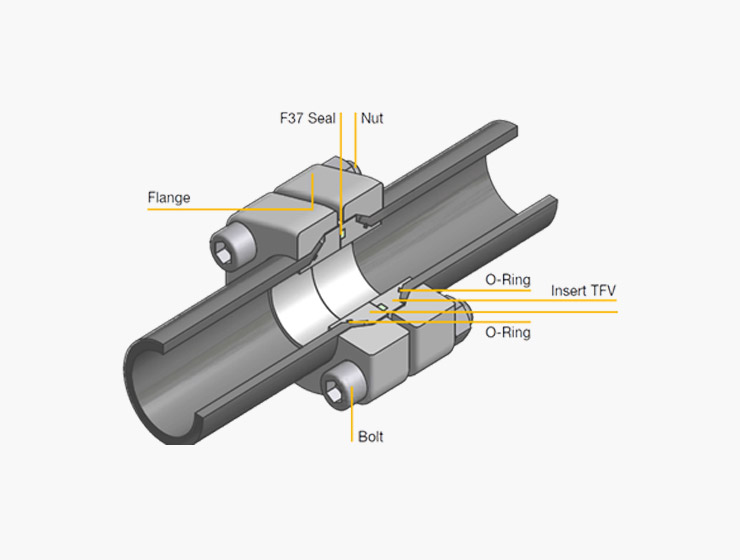

All are designed using Italian and European industrial standards. The mechanical structural parts are made by forging process and equipped with Rexroth Energy-saving system and oil-leak-free pipeline technology. Extrusion press tonnage 11MN to 125MN.

All of the hydraulic components the press is equipped with are manufactured by highly qualified suppliers, such as Rexroth, Oilgear, pal.etc, which is a guarantee of the utmost reliability of the parts and availability of spare parts. The following special features are foreseen.

Special steel forging and European-standard processing ensure dynamic lateral variation within 0.02mm.

Statically determined design guarantees stable, low-speed extrusion, reaching as slow as 0.2mm/s.

Bolster shearing mechanism minimizes secondary die contact.

Rexroth system reduces energy consumption by 30% compared to conventional systems.

Ship-grade, weld-free high-pressure pipelines prevent oil leaks.

Network-enabled system supports remote monitoring and data logging.

South 3 Zhongshan Avenue, Dali Town, Nanhai District, Foshan City, Guangdong Province

sales@cometal.cn、aaron.yan@cometal.cn

phone: 0757- 85553425、+86-13927795968